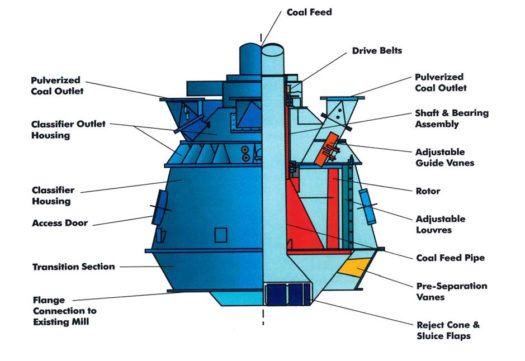

Greenbank Energy Solutions Inc would like to introduce our new product line: HEP Dynamic Classifiers

Featuring:

Improved Fuel and Air Distribution

Today’s stringent environmental regulations, low NOx combustion systems and burners, as well as efficient operation of boilers, demand rigorous control pf the air/coal ratio to each burner from the classifier. The HEP Classifier has the ability to balance the air/coal ratio in each coal pipe served by a classifier, with externally adjustable guide vanes at the outlet to each coal pipe. These guide vanes are designed and positioned to either capture or divert the pulverized coal from entering the outlet. Field experience has demonstrated that individual coal pipes can be balanced with +-2-5% variation.

Improved Particle Size Distribution

The HEP Classifier provides burners with a finer, more evenly ground coal. More precise distribution of the coal particles avoids oversized particles that would otherwise pass, unburned, through the boiler furnace. Better particle distribution also allows the unit to operate at lower excess air levels and allows greater turndown without auxiliary fuel for stabilization. For proper NOx and combustion control, even distribution of the primary air and coal is essential and it is necessary to control the air/coal ratio to each burner.

Increased Boiler Turndown and Fuel Flexibility

Improved particle size distribution, together with more even coal distribution to the burners, produces a more stable flame, reducing the boiler load level where the support fuel must be started. Actual operating experience has shown this to be 10% or more below previous minimum operating levels.

Increased Mill Efficiency

Whether you need additional pulverizer capacity as the result of fuel switching or for a low NOx burner installation, the HEP Classifier can deliver.

Increased Combustion Efficiency

The HEP Classifiers ability to create a finer, more evenly ground coal for the burners, allows optimum combustion efficiency – that means better performance and less unburned carbon in the bottom and fly ash.

Faster Response to Boiler Load Demand

Rotor speed control is provided with a ramp time function that adjusts both the acceleration and de-acceleration of the rotor. This feature creates a temporary difference between the actual rotor speed and the speed demanded by the control system, allowing fast response to boiler load demands.

Installation of the HEP Dynamic Classifier

Custom designed for the specific coal pulverization and burner configurations, HEP Classifiers make retrofit installations easy and economical:

- Low overall height makes conversion of existing mill easy.

- HEP Classifiers come “pre-packaged” for quick flange connection to your existing coal pulverizers and coal burner distribution system.

- Minimal time is required to “re-tune” the boiler and firing system.

- Standard HEP Classifier configurations are available for all manufactures and types of coal pulverizers.