ACOUSTIC PYROMETERS

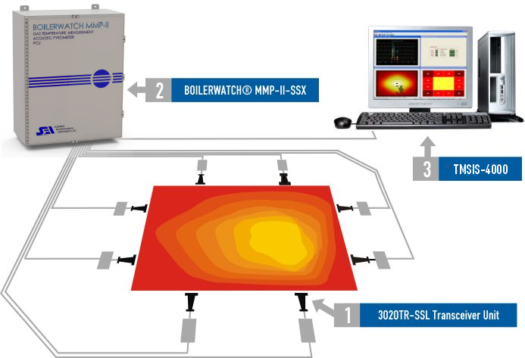

The BOILERWATCH® MMP II acoustic pyrometer is an advanced industrial instrument that provides fully automatic measurement of high combustion-gas temperatures, permitting fuel trimming control within heaters and boilers. The system is completely non-intrusive, and operates on the principal that the speed of sound in a gas is proportional to the temperature of that gas. Acoustic transceivers are mounted on the outside of walls of the heater/boiler, and a high intensity acoustic signal is launched through the gas stream. Since the distance between the sound source and receiver is known and fixed, the average temperature of the gas along the acoustic path is computed from an accurate measurement of the sound signal’s transit time.

The BOILERWATCH® MMP II acoustic pyrometer is an advanced industrial instrument that provides fully automatic measurement of high combustion-gas temperatures, permitting fuel trimming control within heaters and boilers. The system is completely non-intrusive, and operates on the principal that the speed of sound in a gas is proportional to the temperature of that gas. Acoustic transceivers are mounted on the outside of walls of the heater/boiler, and a high intensity acoustic signal is launched through the gas stream. Since the distance between the sound source and receiver is known and fixed, the average temperature of the gas along the acoustic path is computed from an accurate measurement of the sound signal’s transit time.

BOILERWATCH® MMP II systems are available in a variety of configurations. With up to 24 individual path temperatures available, systems may be configured for spatial 2 dimensional temperature mapping, independent temperature measurements, or a combination of both. BOILERWATCH® MMP II systems are easy to install, commission, and operate.

With our Acoustic Pyrometer you can measure the gas temperature in any kind of furnace or boiler and get a distribution map temperature, all in real time. The waveguide can be located in 2, 3 or 4 wall of the furnace or boiler.

Using real-time gas temperature and spatial temperature distribution profile maps from a BOILERWATCH MM-II Acoustic Pyrometer System to reduce out-of balance gas temperature conditions within the horizontal furnace exit plane of a coal fire power boiler, provides a number of highly cost effective benefits.

It has been shown that excess O2 can be reduced by at least 0.5%, which results in a vastly significant increase in fuel efficiency and heat rate. The cost savings from this benefit alone pays for a BOILERWATCH MMP-II system in very short time.

By reducing temperature imbalances and eliminating hot-spots in the FEGT plane, NOx production is cut down at the source. More uniform temperature distribution also reduces thermal stress and increases the service life of critical pressure parts including wall tubes, superheaters and reheaters.

The lastest videos:

- Combined Cycle Power Plant

- Installation Combined Cycle PP

- Glass End Fired

- AP Theory

- Glass Side Fired

- American Fuel & Petrochemical Mfg.

Check out Pyrometer brochures and flyers for various industries:

- BOILERWATCH BENEFITS 2022

- BOILERWATCH CEMENT 2023

- GLASS 2022

- GESTAM BIOMASS 2022

- COMPARISON CAMARA IR-PA 2022

- COMBINED CYCLE PP HRSG Boiler

- BLAST FURNACE

- REFINERY SINOPEC

- REFINERY 2022

- POWER PLANT

- POWER PLANT 2022

Pyrometer Benefits:

- Reduction of excess air is the simplest method in achieving an increase in efficiency. Excess airs are at levels of 10% to 30% depending on the process.

- The optimization of combustion with the Boilerwatch MMP-II-SSX-LD has shown to increase efficiency 2 to 5 percent in power boilers.

- The optimization of the combustion with the Boilerwatch MMP-II-SSX-LD has shown to increase the throughput 2.8 percent in an ethylene reformer.

- Using Burnerwatch™ Acoustic Flame Detector assures correct air fuel mixtures allowing for precise burner control.

- SAVE Money on industrial insurance. Lowers risks associated with accidents and property damages.

- SAVE Money with less critical equipment maintenance and unexpected downtimes.

- Heater monitoring is enhanced when the BOILERWATCH® is installed.

- Tube leaks within the fire box can also be detected by the Acoustic Pyrometer technology.

- Quick and reliable detection of flame impingement on the heater process tubes.

- Monitoring of hot spots.

- Reduce coking buildup.

- Flame Detection on / off.

- Flame fault detection – long flame / wide flame.

- Proactive and non-reactive operations.